FRP Cable Tray

System Overview

FCT cable tray made of corrosion resistant fibre reinforced plastic, comes in standard height of 50mm and 80mm.

FCT FRP Cable Trays are designed specifically for electrical and instrumentation installations, utilizing corrosion-resistant fiber reinforced plastic. These trays are engineered to achieve weight reduction without sacrificing strength, allowing for optimal loading capacity. The lightweight nature of the material ensures resistance to rusting. Additionally, the design enhances health, safety, and environment (HSE) aspects during tray and support equipment installation and lifting. The Cable Trays are offered in five different resin materials, carefully formulated to meet unique project requirements.

FCT FRP Cable Trays are designed specifically for electrical and instrumentation installations, utilizing corrosion-resistant fiber reinforced plastic. These trays are engineered to achieve weight reduction without sacrificing strength, allowing for optimal loading capacity. The lightweight nature of the material ensures resistance to rusting. Additionally, the design enhances health, safety, and environment (HSE) aspects during tray and support equipment installation and lifting. The Cable Trays are offered in five different resin materials, carefully formulated to meet unique project requirements.

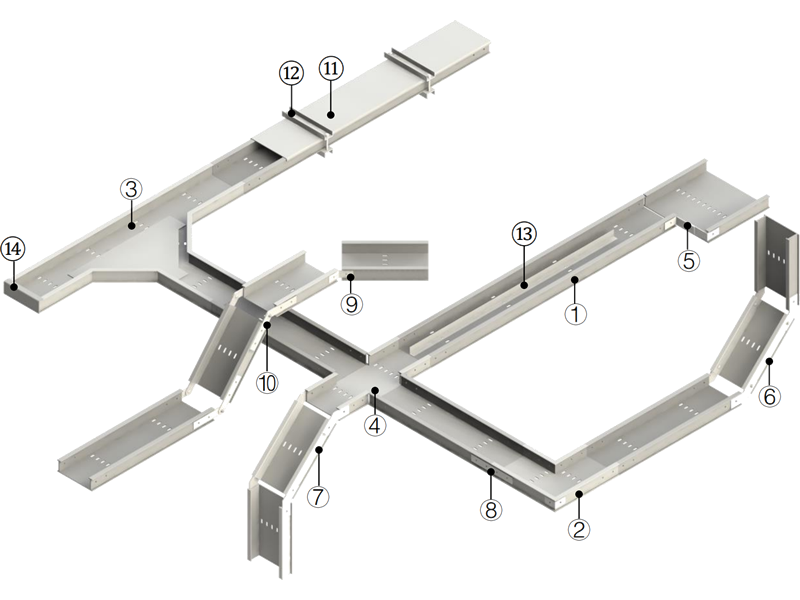

1. straight section: standard width comes in 100, 150, 300, 450, 600, 750, 900, 1000 and 1200mm ,length comes in 3000 and 6000mm, height comes in 100,125 and 150mm.

2. horizontal elbow: standard angle comes in 30, 45, 60 and 90 degress, standard radius comes 300,600 and 900mm.>

3. horizontal tee: standard radius comes 300,600 and 900mm.

4. horizontal cross: standard radius comes 300,600 and 900mm.

5. vertical tee: standard radius comes 300,600 and 900mm.

6. reducer: left reducer as shown, right and straight reducer supplied on request.

7. internal riser: standard radius comes 300,600 and 900mm.

8. external riser: standard radius comes 300,600 and 900mm.

9. combination riser part

10. splice connector

11. horizontal splice connector

12. vertical splice connector

13. reduction splice connector

14. straight flat cover

15. heavy duty cover clamp

16. universal cover clamp

17.flat cover for horizontal elbow

18. barrier strip

19. blind end

20. drop out plate

2. horizontal elbow: standard angle comes in 30, 45, 60 and 90 degress, standard radius comes 300,600 and 900mm.>

3. horizontal tee: standard radius comes 300,600 and 900mm.

4. horizontal cross: standard radius comes 300,600 and 900mm.

5. vertical tee: standard radius comes 300,600 and 900mm.

6. reducer: left reducer as shown, right and straight reducer supplied on request.

7. internal riser: standard radius comes 300,600 and 900mm.

8. external riser: standard radius comes 300,600 and 900mm.

9. combination riser part

10. splice connector

11. horizontal splice connector

12. vertical splice connector

13. reduction splice connector

14. straight flat cover

15. heavy duty cover clamp

16. universal cover clamp

17.flat cover for horizontal elbow

18. barrier strip

19. blind end

20. drop out plate

Basic Parameters

| Material | FRP |

| Finish | / |

| Certification | SGS/BV |

| Width | 50mm/100mm/150mm/200mm/300mm/400mm/500mm/600mm |

| Height | 50mm/80mm |

| Length | 3000mm |

Design Details

Different Height

Different FRP tray heights to give more choice for loading space availability. FCT cable tray comes in standard heights of 50 and 80 mm. Other heights are available on request.

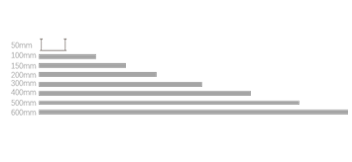

Different Width

Different tray widths to give more choice for loading space availability. FCT cable tray comes in standard widths of 50, 100, 150, 200, 300, 400, 500 and 600 mm. Other widths are available on request.

I-Shaped Side Wall

The I-shaped side Wall design greatly increases the support strength and has the aesthetics of the design.

FRP CABLE TRAY SUPPORT SYSTEM

FRP cable support systems are made of glass reinforced thermoset resin and are designed to combine the light weight of FRP with the strength of metal cable trays. FRP cable tray support systems can be used in a variety of strong corrosive environments and are non-conductive.

FRP cable tray cable tray as a kind of non-metallic cable tray is light in weight, which makes it easier to install, reduces the occurrence of hoisting accidents, and reduces shipping costs. FRP cable trays are available in a variety of colors and can be customized according to requirements. During the extrusion process, a protective layer can be added to increase the corrosion resistance and anti-ultraviolet characteristics of FRP cable trays.

We manufacture two different FRP cable trays, Ladder FRP Cable Tray and FRP Tray Cable Tray Love. And available in a variety of widths, it is the ideal support solution for pipe and cable routing. FRP tray trays are available with solid and perforated bottoms and a variety of height options for different pipeline cable supports.

Both FRP ladder cable tray and FRP tray cable tray can be made of a variety of different resins, and can provide a complete range of installation accessories.

FRP cable trays can be formed by extrusion or compression molding. The pultrusion process uses a combination of unidirectional and cross-strand glass rovings and matting sheets that are resin-impregnated and pulled through a heated die to produce very strong and well-structured profiles, often more robust than compression molding production.

Different resins can be used to produce cable trays with different properties. Common resins are polyester, acrylic and vinyl ester.

Over the years, as a FRP cable tray support systems manufacturer, our FRP cable trays have been fully verified and tested in harsh environments such as offshore oil and LNG industries. The support strength of our FRP cable trays is equal to or even higher than that of metal cable trays, while retaining the non-conductive, non-magnetic and corrosion-resistant properties of FRP, which reduce the risk of radio waves, radar and microwaves.

FRP cable tray cable tray as a kind of non-metallic cable tray is light in weight, which makes it easier to install, reduces the occurrence of hoisting accidents, and reduces shipping costs. FRP cable trays are available in a variety of colors and can be customized according to requirements. During the extrusion process, a protective layer can be added to increase the corrosion resistance and anti-ultraviolet characteristics of FRP cable trays.

We manufacture two different FRP cable trays, Ladder FRP Cable Tray and FRP Tray Cable Tray Love. And available in a variety of widths, it is the ideal support solution for pipe and cable routing. FRP tray trays are available with solid and perforated bottoms and a variety of height options for different pipeline cable supports.

Both FRP ladder cable tray and FRP tray cable tray can be made of a variety of different resins, and can provide a complete range of installation accessories.